Advanced Cane Sugar Processing Chemicals: Enhance Pureness and Taste

Advanced Cane Sugar Processing Chemicals: Enhance Pureness and Taste

Blog Article

Transform Your Manufacturing Line With Cutting-Edge Walking Cane Sugar Processing Chemical Solutions

In the world of production effectiveness and quality, the use of sophisticated chemical services in cane sugar handling has emerged as a crucial variable for contemporary industrial procedures. Cane Sugar Processing Chemicals. From improved sugar removal processes to cost-effective assembly line options, the assimilation of sophisticated innovations is positioned to transform standard techniques. By incorporating innovative methods to sugar refining and high quality enhancement with chemical developments, businesses can not just maximize their procedures but additionally welcome lasting and green practices. As industries develop to fulfill the demands of an altering market landscape, the prospective advantages of these chemical options in changing manufacturing lines are vast and fascinating.

Boosted Sugar Extraction Processes

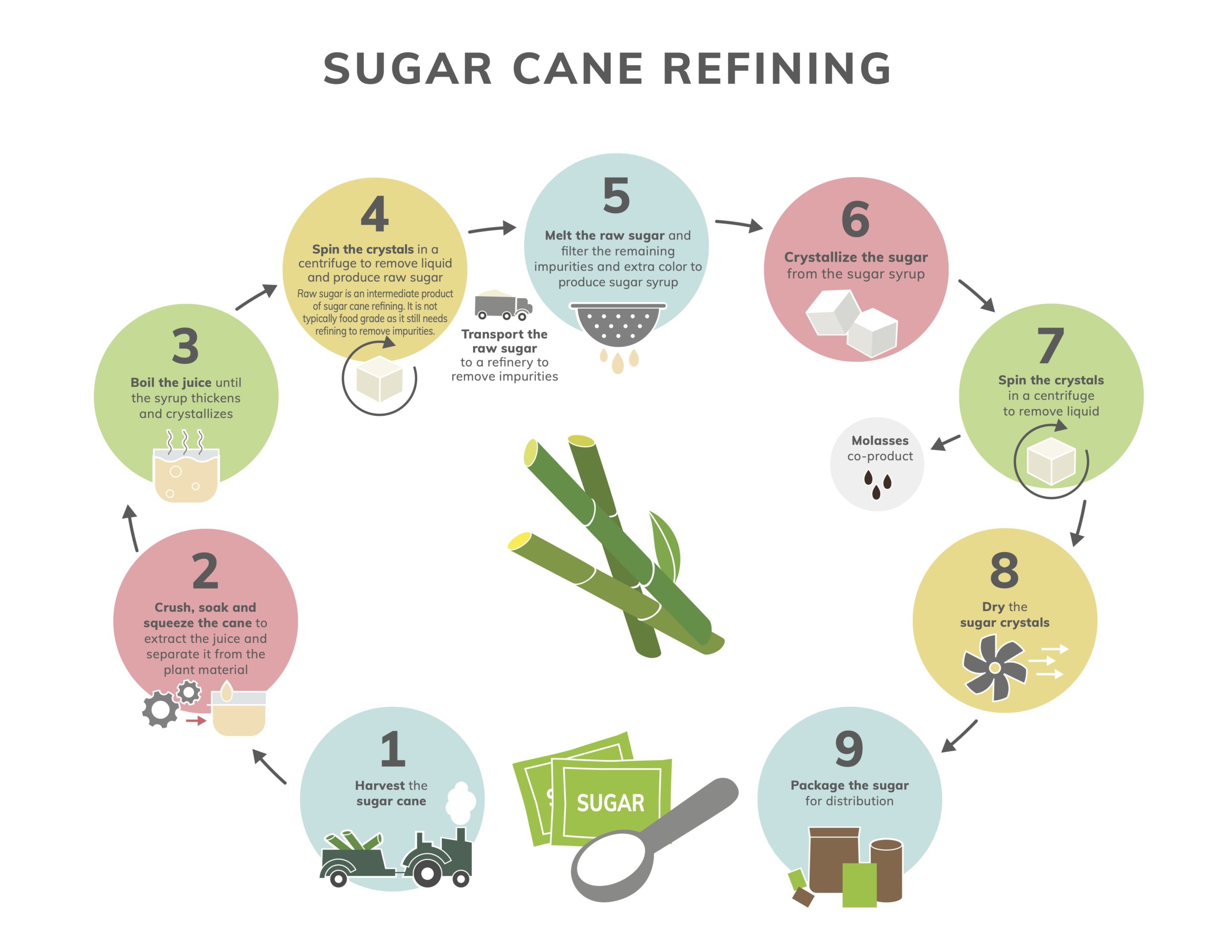

Innovative methods in sugar removal have significantly enhanced the performance and top quality of walking cane sugar processing. Enzymes, like cellulases and pectinases, damage down cell walls and boost the release of sucrose from the sugar walking stick fibers.

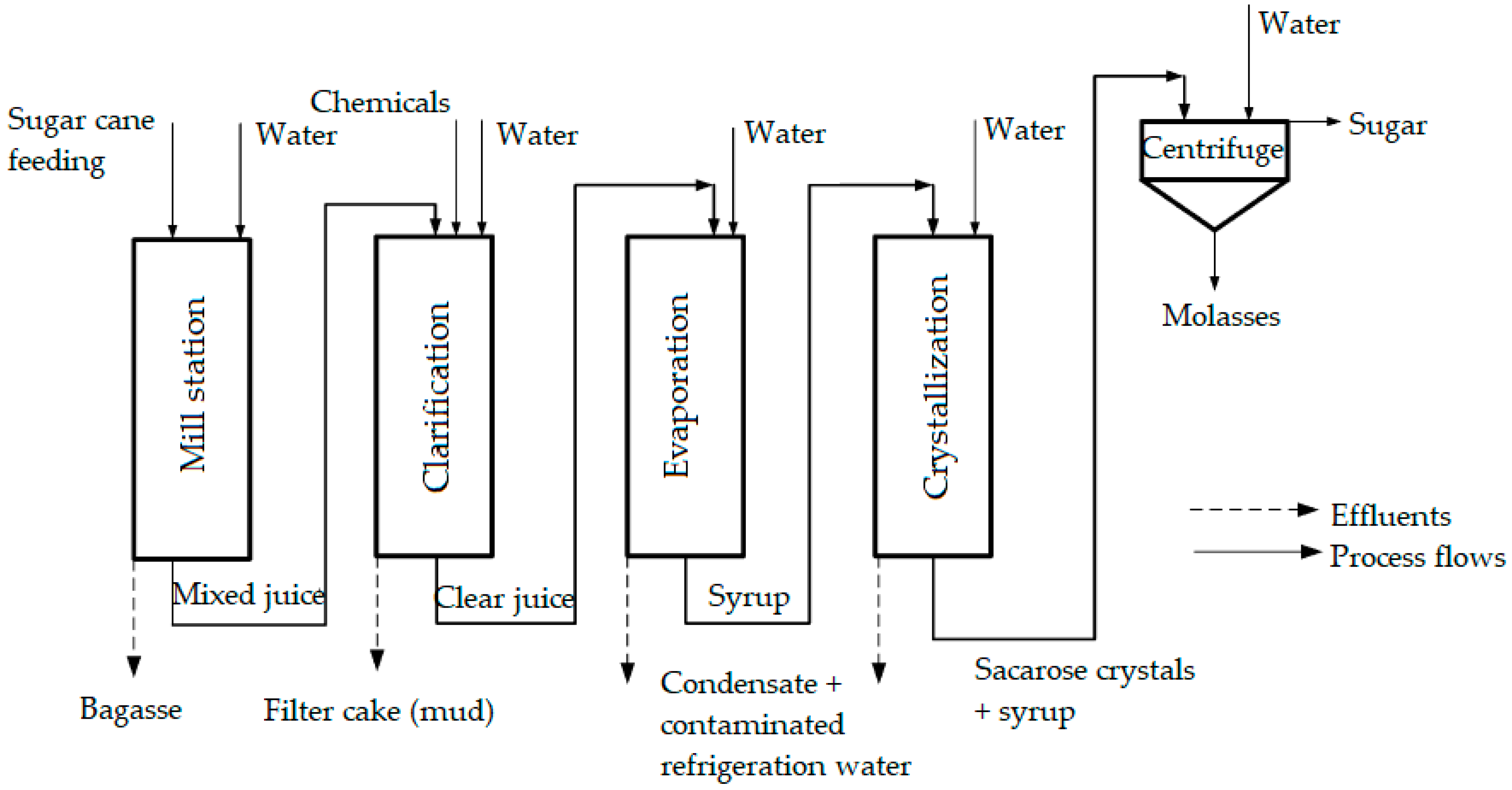

Moreover, the intro of diffusion-based removal systems has reinvented the sector. By utilizing a series of diffusers, sugar processors can accomplish higher extraction rates contrasted to traditional approaches. Cane Sugar Processing Chemicals. The diffusion process entails the removal of sugar from the cane making use of a countercurrent flow of water, making sure maximum sucrose removal

This not just conserves power yet also protects the high quality of the removed sugar by avoiding caramelization. These advancements in sugar extraction techniques underscore the industry's dedication to boosting effectiveness and item high quality.

Improved Sugar Refining Strategies

Additionally, the execution of modern formation techniques has enabled for better control over crystal size and development, resulting in a much more constant product quality. Modern sugar refining techniques likewise involve the use of automated systems and advanced tracking tools to enhance process criteria and make certain exact control over each phase of refining. These innovations not just enhance the effectiveness of sugar refining processes but likewise add to the production of premium refined sugar that meets the rigorous criteria of the market.

Cost-efficient Production Line Solutions

The advancement of sugar refining strategies has actually led the way anchor for the expedition of cost-efficient assembly line services in the sugar processing sector. To improve operational performance and success, sugar manufacturers are increasingly transforming to cutting-edge techniques that improve manufacturing procedures while keeping prices convenient.

One efficient strategy for expense decrease is the execution of sophisticated automation innovations. Automated systems can significantly boost productivity by minimizing hand-operated labor requirements, minimizing errors, and boosting total production speed. By buying advanced equipment and equipment, firms can maximize their manufacturing lines and attain higher outcome degrees without jeopardizing on top quality.

In addition, the use of energy-efficient solutions is another crucial facet of cost-effective manufacturing line monitoring. By embracing sustainable practices and integrating environmentally friendly technologies, sugar handling plants can lower energy consumption, decrease operational costs, and add to a greener setting.

Quality Enhancement With Chemical Innovations

Enhancing the quality of cane sugar handling through tactical chemical developments is crucial for ensuring constant product quality in the sector (Cane Sugar Processing Chemicals). By incorporating cutting-edge chemical options into the assembly line, sugar manufacturers can boost the top quality of their final result, satisfying the boosting needs of consumers and market guidelines

Chemical developments play a crucial function in boosting the purity, shade, flavor, and general wikipedia reference sensory experience of cane sugar. Progressed information agents can assist remove contaminations much more effectively, resulting in a clearer and cleaner final product. In addition, using specialty enzymes can maximize the conversion of sucrose into fructose and sugar, enhancing the sweet taste and texture of the sugar.

In addition, chemical services can assist in extending the life span of walking stick sugar items by hindering microbial growth and protecting against discoloration. By keeping item stability and freshness, manufacturers can meet consumer expectations for top quality, lasting sugar items. To conclude, leveraging chemical innovations for quality improvement in walking stick sugar handling is a strategic approach that can drive competitiveness and success in the sector.

Sustainable and Environment-friendly Practices

Strategically applying sustainable and environmentally friendly methods in walking cane sugar processing not just enhances item high quality yet additionally promotes ecological stewardship and long-term stability in the sector. Accepting sustainable techniques entails minimizing water use, power usage, and waste generation throughout the manufacturing procedure. Implementing cutting-edge innovations such as water reusing systems, energy-efficient machinery, helpful site and waste administration solutions can considerably minimize the ecological footprint of cane sugar processing plants.

Furthermore, taking on eco-friendly techniques in sourcing basic materials, such as sugarcane, can contribute to biodiversity preservation and lasting land management. Participating in liable agricultural practices, like chemical-free farming techniques and habitat conservation, not only guarantees a long-lasting supply of top quality resources however also safeguards ecosystems and sustains local neighborhoods.

Conclusion

Report this page